Simplify Jobsite Compliance with Digital Safety Logs

Managing jobsite safety is critical for construction, manufacturing, and other high-risk industries.

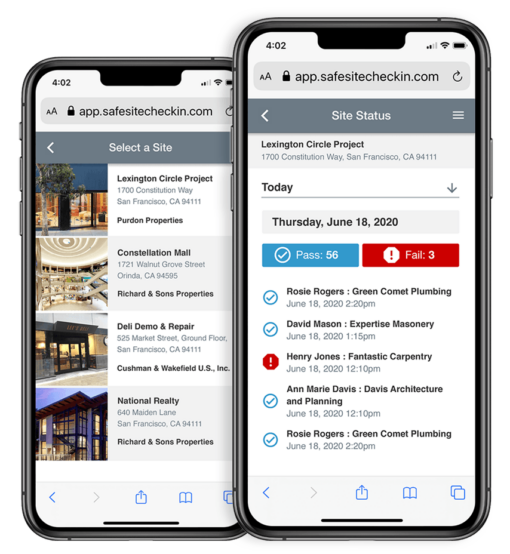

Safe Site Check In allows site and safety managers to remotely track attendance, enforce safety protocols, engage with workers, warn of hazards, and document compliance.

By replacing paper logs with digital tools, you reduce administrative burden, gain real-time insights and build a safety culture.

Benefits for Construction and Safety Managers

Improve Jobsite Safety

Ensure every worker and visitor understands safety protocols, reduce incidents, lower insurance costs.

Improve EHS Manager Productivity

Remotely monitor all jobsites and customize safety check-ins for particular project risks.

Save Superintendents Time

Automate everyday jobsite EHS communications to free up jobsite supervisors for higher-value work.

Permanent, Private, Secure Compliance Records

Attendance data for incident research. Proof of hazard awareness. Proof of visitor risk acceptance. Improve risk management and gain the confidence of project and facility owners.

How Safe Site Check In Works

All data is securely stored in real time and accessible for compliance reporting. Higher volume sites can create digital badges and use tablets or phones to scan workers in.

Key Features of Safe Site Check In

Real-Time Attendance Tracking

Monitor who is on-site, when they arrived, and how long they stayed—all without manual data entry.

Paperless Compliance Documentation

Securely store attendance, questions and answers to screening questions, safety certifications, training records, and liability waivers in the cloud.

Customizable Safety Protocols

Tailor check-in workflows with health screenings, hazard alerts, and jobsite-specific requirements.

Training and Onboarding Tools

Share safety videos or documents during onboarding to prepare workers for project-specific risks.

Emergency Action Plans

Communicate with workers on site during emergencies like weather, natural disasters or accidents.

Safety Data Sheets

Provide everyone access to hazmat safety data sheets without printing and delivering binders.

Capture Workforce Profile Data

Capture worker certifications, licenses, experience & training data for use by EHS and superintendents.

Get Started with Safe Site Check In Today

Experience the simplicity of digital safety check-ins. Schedule a free demo with us so you can see firsthand how Safe Site Check In saves time, reduces risk, and ensures compliance.

Frequently Asked Questions

What is a digital safety daily log?

A digital safety daily log automatically cloud-stores jobsite and workplace attendance, compliance activities, and incident reports, replacing traditional paper logs.

How does Safe Site Check In ensure compliance?

The app captures safety certifications, training records, and health screenings during check-in, ensuring all workers meet jobsite-specific requirements.

Is it easy to set up?

Yes, Safe Site Check In requires no IT support. Simply display QR code signage and start using the platform immediately. No software to download and install.

Can I customize the check-in process?

Absolutely. Tailor workflows to include jobsite-specific safety protocols, health screenings, or notifications for supervisors.

Is the data secure?

Yes, all data is encrypted and securely stored in the cloud, accessible only to authorized personnel.

Who can benefit from Safe Site Check In?

Safety managers, jobsite supervisors, facility managers and EHS professionals in hard-hat industries and other high risk worksites.