Construction projects have many stakeholders, all of whom are strongly affected by national and global trends in different ways. More than most industries, construction firms need to separate hype from reality when adopting a strategy to thrive. We discuss how firms should plan and invest in construction management software as a response to the unstoppable trends in technology, climate change, demographics, national security and politics

What Are these 7 Trends Affecting Construction Management Software?

Generally Available Technology Grows Everyday

Technology-driven transformation happens continuously to enhance productivity, efficiency, and safety, but construction is a laggard and late adopter (for reasons we discuss here). Digital transformation is well underway in other industries and uses data-driven analytics to optimize processes, predict risks, and improve resource allocation.

Construction is even today often paper-form oriented and workflows and communications are slow, noisy and ultimately costly. As a response to the Covid pandemic, mobile access technologies now enable collaboration and project management remotely, enhancing flexibility and retaining talent. But remote working is not an option for most field work in construction. And even though everyone now has a smartphone, many construction sites don’t allow their use onsite.

AI covers a wide range of technologies including pattern recognition, machine learning, language translation and now generative AI. More recently AI based on large language models is automating human expertise across all professions and beginning to make inroads into construction. Most such applications act as “intelligent assistants” to professionals as long as there is a validated corpus of textual knowledge the AI engines can learn from.

Finally, AR/VR is approaching consumer-level affordability. While most applications are for entertainment, potential use cases for accelerated training may enter AEC soon.

ConTech Investment and Construction Management Software

Venture capitalists and large software platforms are investors in ConTech, an umbrella term for transformative technologies specifically for the AEC industry. Examples include: VDC, BIM and “digital twin”, which produce virtual replicas of the to-build physical structures. They optimize the design-builder interface.

Drones and other video technologies are being developed for real-time monitoring of the as-built structures. 3D printing, robotics and pre-fabrication attempt to replace human trade labor and materials either in the field or offsite. All the large construction management software firms are aggressively deploying chatbots based on proprietary large language models.

Sustainability Initiatives

The sustainability trend is driven by both governments and economics. Climate change response is driving the adoption of green building practices, including the use of sustainable, and energy-efficient building materials.

The integration of smart devices (aka the “internet of things”) attempts to enhance the efficiency, sustainability, and well-being of the built environment: individual buildings and even “smart cities”. The European Commission defines a smart city as a “technologically modern urban area that uses different types of electronic methods and sensors to collect specific data”, for better resource use and less emissions.

Demographic Tsunami

AEC has an historic skilled workforce deficit, a topic we discuss here. The great financial crisis of 2008-10 depressed workers from joining the industry and construction is a profession where on the job experience is essential. Too many experienced workers of all types are now retiring and cannot be replaced quickly enough. The problem exists across the world.

Climate Changes Everything

Currently, the US is pivoting away from fossil fuels toward wind, solar and other renewable energy at a fast rate. A New York Times-article from last year titled “The Clean Energy Future Is Arriving Faster Than You Think” explains that both wind and solar power are breaking records, and renewables are now expected to overtake coal by 2025 as the world’s largest source of electricity.

The shift towards renewable sources of energy is the result of government funding when President Biden signed a trio of laws during his first two years in office that allocated unprecedented funds for clean energy. One of these laws, the Inflation Reduction Act, provides tax breaks related to electric vehicles, heat pumps and energy efficiency upgrades, solar panel and wind turbine manufacturing and clean hydrogen production.

The effect on AEC is the type of structures to be built, which requires new engineering expertise, the location of the projects, and the nature of the funder – if government funded, mandates for union labor and locally sourced materials may apply.

National Security Reaches Construction

President Biden’s CHIPS Act from 2022 created almost 800,000 manufacturing jobs and more than $400 billion in private sector investments in two years. Paul Krugman argued in a New York Times article with the title “Making Manufacturing Greater Again” that Biden’s incentives to bring manufacturing jobs back to the US are more successful than his predecessor and created increased demand for a wide range of U.S.-produced manufactured goods, from batteries to electric motors.

Krugman noted that business responded to that prospective increase in demand by investing a lot more in American manufacturing than it had “for a long time”. Forty years, in our opinion.

As with climate change, the effect of this trend on AEC is the type of structures to be built, which requires new engineering expertise, the location of the projects, and the nature of the funder – if government funded, mandates for union labor and locally sourced materials may apply.

Health and Safety Expectations

At least recently, there is a growing focus on safety protocols and wearable technology for worker protection. Recent regulatory changes require construction companies to stay updated on evolving regulations related to safety, sustainability, and construction practices.

Digital safety is becoming as important as physical safety onsite: As construction becomes more reliant on technology, ensuring data security and protecting against cyberattacks is crucial.

Traditionally the industry has fought any new regulations, relying on insurance & private lawsuits to compensate for the costs of health and safety incidents, up to and including death. Construction management software firms nor ConTech investors have prioritized safety.

Practical Responses for Selecting Construction Management Software

Not all responses to these mega- trends are having a transformative impact on construction. In some cases, their impact is vastly exaggerated.

ConTech appears to be a VC marketing term attempting to motivate investors rather than sell products and services. For example, digital twins are mostly 3D models under a new name. The near-term value of ConTech for higher productivity, efficiency, and safety for construction projects onsite is debatable.

Generally available technology is making incremental inroads. Digital transformation is a prerequisite for a successful data-driven approach. But the industry needs to wean itself off paper forms and informal communications first. Some reasons why field operations shuns digital can be found here.

Construction companies used to make a distinction between office and field work, but that distinction is blurring due to technological advancements such as apps that enable remote collaboration and project management.

The increasing functional breadth of software platforms such as Procore, Trimble and Autodesk is most practical, if financially difficult for smaller contractors.

One exception here is AI. Associated Builders and Contractors (ABC)’s artificial intelligence technology guide for the construction industry mentions no less than 20 different use cases for AI in construction, including intelligent site monitoring, energy management, and predictive maintenance, and chatbot assistance to managers to obtain and apply knowledge more efficiently in support of their daily managerial tasks. There are multiple benefits of using chatbots instead of humans, as they’re available 24/7, which helps construction companies save time and costs.

Sustainability varies widely, as green building practices and the use of innovative materials are only applied when they’re required by project owners or are built into local regulations. This means their impact is limited.

Smart cities impact the built environment, they are more interesting for the design and maintenance phase of a construction project. Everywhere on earth, city councils compete with each other over urban prestige projects, making full use of the hype that surrounds the term “smart city”.

Safety initiatives in construction are mostly hype, at least in the USA, where safety is considered a “cost”. Improving physical safety is nothing new, and construction is not yet recognized as a vulnerable industry in terms of cybersecurity (infrastructure utilities get more attention). Increasing regulatory changes in the industry could also be rolled back in the future as political regimes change, so it’s not possible to say if and how they will affect the industry.

Demographics and workforce dynamics in construction, however, are immediate and forcing a response. This is the biggest challenge for the construction industry today and perhaps its biggest driver for long deferred changes to improve productivity and efficiency.

Both are essential to compensate for missing workers. For example, to solve the labor shortage problem, construction companies are adopting strategies like increased training, improved worker benefits, and automation. They’re even lobbying for more guest worker visas.

Labor replacement strategies include the rise of modular construction, prefabrication, and renovation vs new building for faster completion times and reduced cost. But the effects of modular construction, prefabrication, and renovation projects have been limited apart from some pilot projects.

Government initiatives to stimulate domestic manufacturing and energy transition are already having a positive effect on the economy and construction in particular. Businesses such car makers are overhauling existing manufacturing facilities and processes, as well as building new plants in preparation for a world beyond gasoline-powered cars and trucks.

By August 2023, Biden’s new laws allocating unprecedented funds and tax incentives for clean energy prompted companies to announce at least $230 billion in manufacturing investments, including a new $3.6 billion electric truck factory by Tesla in Nevada. Of course, future administrations have vowed to roll many of these laws back in spite of the economic benefits.

Respond with an incremental digital approach selecting Construction Management Software

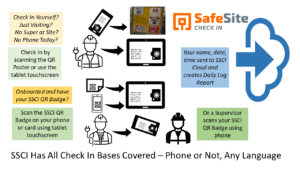

Construction companies face a shortage of skilled labor and are turning to automation for increased productivity and efficiency. This poses a challenge for site managers who must oversee less experienced workers, leading to higher accident risks. SSCI offers Safe Site Check In, a digital solution that automates processes and ensures only safety-compliant workers have access.

Due to the shortage of skilled labor, construction companies need to automate tasks to be more productive and efficient. Site managers face the challenge of managing job sites with younger, less experienced workers, increasing the risk of accidents. Builders must adapt quickly. SSCI offers a digital solution, Safe Site Check In, which automates essential processes and ensures access only for workers who meet safety requirements.

SSCI offers a digital yet low-risk approach to Make Jobsite Management Easy (™). Products like our Safe Site Check In mitigate by automating essential processes used on every jobsite, such as granting access only to onboarded workers.

Project, superintendents and safety managers and HQ stakeholders always know who is on a construction site, when, why and how long. SSCI helps onsite managers to focus on important tasks that require human interaction and allows project and safety managers to do more of their work remotely.

Digital tools like SSCI help create a “single source of truth” about projects. For example, in case digital log files need to be handed over to other stakeholders in case of an accident. Log data captured in real-time and cloud-stored can be accessed from anywhere with an internet-connected device.

David Brian Ward is a CEO and Founder of Safe Site Check In LLC, a digital jobsite management platform launched in 2020 for the Construction industry. With over 40 years of experience in the technology industry, having launched and grown several successful companies. Mr. Ward is a now a SaaS entrepreneur and innovation leader in the Construction industry.